AUTHOR: Xuan Xu

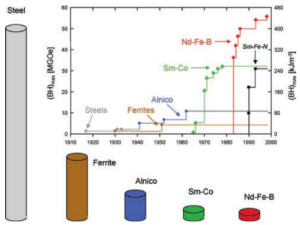

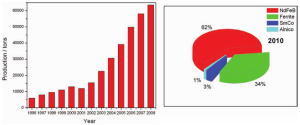

Our daily environment is significantly dependent on the materials with outstanding magnetic properties. Hard magnetic materials have been successfully exploited with enhanced energy densities (BH)max, starting from ≈1 MGOe for steels discovered during the early part of the century, increasing to ≈3 MGOe for hexagonal ferrites, and finally peaking at ≈56 MGOe for neodymium-iron-boron magnets in the past thirty years. This historical evolution spanning nearly 100 years of these permanent magnets is shown in Figure 1 [1]. Recently, much more attention is paid on rare-earth permanent magnets due to the growing demand for energy efficient technologies. These magnets are very efficient at various operating temperatures. The excellent magnetic properties of NdFeB-based magnets result from the Nd2Fe14B phase which is characterized by a high saturation magnetization (µ0MS) of 1.6 T, a high anisotropy field (µ0Ha) of ~7.5 T and a Curie temperature (Tc) of 321 ℃ [2, 3]. So Nd2Fe14B based magnets are often chosen for small and light applications.

Figure 1. Development in the energy density (BH)max at room temperature of hard magnetic materials in the 20th century and the percentage sales for 2010 of the major permanent magnets in the world, from Ref. [1]

A hard magnetic compound that is suitable for a permanent magnet application must have a sufficiently large anisotropy field (Ha). Ha is the theoretical limit of coercivity for spins coherent rotation, while the coercivities (Hc) of industrially processed bulk magnets have never exceeded Ha/3. This is becausee a certain fraction of nonmagnetic phase (>10%) must be present in the bulk magnets in order to have a heterogeneous microstructure which induces the coercive force. Many papers have pointed out the poor thermal stability of Nd2Fe14B, this results in a very rapid decrease of coercivity with temperature. Another serious problem is the poor corrosion resistance which comes from the Nd-rich grain boundary phase and is very sensitive to humidity [4]. Therefore, finding a new hard magnetic compound, whose saturation magnetization is higher than that of Nd2Fe14B and with a sufficient magnetic hardness of Hc > Ha/3 is of great interest [5]. Additionally, the worldwide concern for rare-earth resources has triggered the development of new high-performance permanent magnets with lower rare-earth element content and may result in higher anti-corrosion property. During the rare-earth crisis of 2011, the European Union (EU) investigated several possible solutions to alleviate the shortages of rare-earth resources. In the DEMETER project, researchers are working on the synthesis of novel hard permanent magnets with lower rare-earth element content.

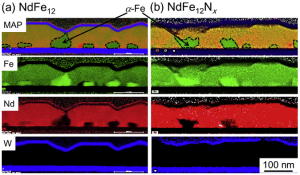

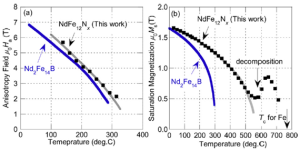

Since 1990, the discovery of the nitrogenation effect on the relevant rare earth-iron intermetallics has attracted great interest in the study of rare earth nitrides [6-8]. The study of nitrogenation effect reveal that the interstitial nitrogen dissolution indeed enhances the magnetic properties: µ0Ha, µ0MS and Tc. It is quite logical that the nitrogenation of Nd2Fe14B may improve the magnetic properties. However, experimental results suggested [9] that interstitial modification of Nd2Fe14B using N indeed resulted in an increase in Tc of 60 K, but with a reduction in Ms and anisotropy field.Other studies even have showed that nitrogenation may lead directly to decomposition [10, 11]. So nitrogenation of Nd2Fe14B fails to enhance its magnetic properties. At the same time R2Fe17N3 (2:17, R = rare-earth element) [12, 13] and RFe12-xMxN (1:12, R= rare-earth element, and M = Mo, Ti and V) [7, 14, 15] rare-earth/iron compounds have received extensive attention. These nitrides exhibit high intrinsic magnetic properties which are comparable with those of Nd2Fe14B, or even better in terms of Curie temperature [16] and the corrosion stability [17]. The average increase in Tc caused by introducing nitrogen into RFe12-xMxN is ~ 200 K [18] which is desirable for these magnets applications in the high-temperature operation conditions. Among these RFe12-xMxN alloys, NdFe12-xMxN magnets show a higher saturation magnetization [7, 16]. Furthermore, the relative content of the rare-earth element Nd in NdFe12-xMxN (~ 7.6 at.%) is much lower compared to other rare-earth permanent magnets such as R2Fe17N3 and Nd2Fe14B (~ 12.5 at.%) magnets. However, RFe12 compounds are metastable which can only be obtained by replacing the Fe with a third element M (M = Mo, Ti and V). As a consequence, µ0MS of NdFe12-xMxN compounds is lower than that of Nd2Fe14B, due to the substitution of a non-magnetic element for Fe to stablize the ThMn12 structure. For example, M. Akayama [19] and S. Suzuki [20] reported that µ0MS of NdFe11TiN and NdFe7Co3TiN1.3 is, respectively, 1.48 T and 1.50 T, which are lower than that of Nd2Fe14B (1.60 T). If x in NdFe12-xMxN compounds can be reduced, large magnetization will be achieved which has been approved by T. Miyake et al [21] theoretically via first-principles study. Although the pure NdFe12 phase is metastable, recently, Hirayama et al [5, 22]. obtained the NdFe12Nx phase via co-sputtering of the Nd and Fe on textured W (110) substrates and subsequent annealing in nitrogen atmosphere (Figure 2 left). They acheived excellent intrinsic hard magnetic properties of µ0MS ≈ 1.66 ± 0.008 T, µ0Ha ≈ 8 T and Tc ≈ 550 ℃ (Figure 2 right) that are superior to those of Nd2Fe14B.

Fig. 2 Left: STEM/EDS image of (a) NdFe12 and (b) NdFe12Nx; Right: (a) Anisotropy field (µ0Ha) and (b) saturation magnetization (µ0MS) as a function of temperature along with those of Nd2Fe14B, from Ref. [5]

Although co-sputtering, the method for preparing NdFe12Nx compounds Hirayama used, is technically interesting, it is a procedure that is very costly due to the required high vaccum conditions and relatively low deposition rates that makes it difficult to prepare thick film coatings. In contrastn, the electrochemical reduction is quite attractive due to its simplicity, high deposition rates, and its ability to make single- and multi-layers of different metal or alloy, ease of scale-up to large surface area and the applicability to wide variety of different shapes and surface geometries. Unfortunately, there are no recent reports on the electrodeposition of NdFe12 phase. However, some articles on electrodeposition of NdFeB magnets have already been published which provide some guidelines for the synthesis of NdFe12 phase through electrochemistry. If NdFe12 alloy could be well electrodeposited on suitable substrates first, then the nitrogen could be introduced in-situ via the use of N-containing regents or ex-situ via post annealing in N2 atmosphere at 400-500 ℃ to form NdFe12Nx.

References

- Gutfleisch, O., et al., Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Advanced Materials, 2011. 23(7): p. 821-842.

- Luo, Y. and N. Zhang, TEMPERATURE-VARIATION OF DOMAIN-STRUCTURE AND MAGNETIZATION IN NDFEB MAGNETS. Journal of Applied Physics, 1987. 61(8): p. 3445-3447.

- Sagawa, M., et al., Magnetic properties of rare‐earth‐iron‐boron permanent magnet materials. Journal of Applied Physics, 1985. 57(8): p. 4094-4096.

- Sagawa, M., REVIEW OF SINTERING PROCESS-DEVELOPMENT FOR ND-FE-B. Journal of Materials Engineering, 1991. 13(2): p. 95-101.

- Hirayama, Y., et al., NdFe 12 Nx hard-magnetic compound with high magnetization and anisotropy field. Scripta Materialia, 2015. 95: p. 70-72.

- Yang, Y.C., et al., STRUCTURAL AND MAGNETIC-PROPERTIES OF NITRIDE COMPOUNDS OF THE TYPE R2FE17NX, R2FE14BNX AND RTIFE11NX. Journal of the Less-Common Metals, 1991. 170(1): p. 37-44.

- Yang, Y.C., et al., MAGNETOCRYSTALLINE ANISOTROPIES OF RTIFE11NX COMPOUNDS. Applied Physics Letters, 1991. 58(18): p. 2042-2044.

- Yang, Y.C., et al., THEORETICAL EXPLANATIONS OF MAGNETOCRYSTALLINE ANISOTROPY BEHAVIORS IN RTIFE11NX COMPOUNDS. Journal of Applied Physics, 1991. 70(10): p. 6574-6576.

- Ying-chang, Y., et al., Structural and magnetic properties of nitride compounds of the type R 2 Fe 17 N x, R 2 Fe 14 BN x and RTiFe 11 N x. Journal of the Less Common Metals, 1991. 170(1): p. 37-44.

- Blach, T. and E.M. Gray, Nitrogen-induced degradation of Nd 2 Fe 14 B. Journal of magnetism and magnetic materials, 1998. 177: p. 985-986.

- Önneby, C., T. DebRoy, and S. Seetharaman, Experimental studies on nitrogen solubility in Nd 2 Fe 14 B alloy in the temperature range 773–1143 K. Journal of magnetism and magnetic materials, 1993. 127(3): p. 307-314.

- Zouganelis, G., M. Anagnostou, and D. Niarchos, MOSSBAUER AND MAGNETIC STUDIES OF THE LU2FE17NX, SM2FE17NX INTERMETALLIC COMPOUNDS. Solid State Communications, 1991. 77(1): p. 11-16.

- Jaswal, S.S., et al., ELECTRONIC AND MAGNETIC-STRUCTURES OF THE RARE-EARTH COMPOUNDS – R2FE17N ZETA. Physical Review Letters, 1991. 67(5): p. 644-647.

- Yang, J.B., et al., Theoretical calculation on the magnetocrystalline anisotropy of NdFe10.5V1.5Nx. Solid State Communications, 1997. 104(10): p. 615-618.

- Yang, Y.C., et al., FORMATION AND CHARACTERISTICS OF HARD MAGNETIC-MATERIALS – PR(MO,FE)12NX. Applied Physics Letters, 1992. 61(22): p. 2723-2725.

- Yang, Y.C., et al., STRUCTURAL AND MAGNETIC-PROPERTIES OF RMO1.5FE10.5NX. Journal of Applied Physics, 1993. 74(6): p. 4066-4071.

- Wang, Y.Z., et al., Hard magnetic properties of interstitial compounds Sm-3(Fe,Cr)(29)X-y (X = N, C). Journal of Alloys and Compounds, 1998. 281(1): p. 72-75.

- Stadelmaier, H.H. and E.T. Henig, PERMANENT-MAGNET MATERIALS – DEVELOPMENTS DURING THE PAST 12 MONTHS. Journal of Materials Engineering and Performance, 1992. 1(2): p. 167-174.

- Akayama, M., et al., PHYSICAL-PROPERTIES OF NITROGENATED RFE11TI INTERMETALLIC COMPOUNDS (R=CE, PR AND ND) WITH THMN12-TYPE STRUCTURE. Journal of Magnetism and Magnetic Materials, 1994. 130(1-3): p. 99-107.

- Suzuki, S., N. Inoue, and T. Miura, MAGNETIC-PROPERTIES OF RFE11-XCOXTINY (R-ND, PR) COMPOUNDS WITH THMN12 TYPE-STRUCTURE. Ieee Transactions on Magnetics, 1992. 28(5): p. 2005-2009.

- Miyake, T., et al., First-Principles Study of Magnetocrystalline Anisotropy and Magnetization in NdFe12, NdFe11Ti, and NdFe11TiN. Journal of the Physical Society of Japan, 2014. 83(4).

- Hirayama, Y., T. Miyake, and K. Hono, Rare-Earth Lean Hard Magnet Compound NdFe12N. JOM, 2015. 67(6): p. 1344-1349.

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)