End-of-life or scrap Sm-Co permanent magnets are a valuable resource of cobalt, samarium, copper and iron. A solvometallurgical recovery route for indirect recycling of Sm-Co permanent magnets was developed by SIM² KU Leuven SOLVOMET researchers. The method is based on non-aqueous solvent extraction to minimize water consumption. The work is published in Separation and Purification Technology. (MO/PTJ, Leuven, 25/03/2019)

SmCo magnets

End-of-life or scrap Sm-Co permanent magnets are a valuable resource to recover cobalt, samarium, copper and iron. Interestingly, the most valuable metal from Sm-Co permanent magnets is not the rare-earth samarium, but cobalt, a transition metal. Indirect recycling allows to differentiate the end applications of the recovered metals, especially of cobalt whose demand for electric-vehicle batteries is rapidly increasing.

New solvometallurgical recovery route

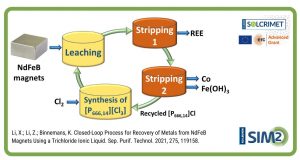

A solvometallurgical recovery route (cf. position paper on this branch in extractive metallurgy) was developed with the aim to recycle Sm-Co permanent magnets, while minimizing the water consumption. In fact, the Sm-Co permanent magnets were leached in a 2 mol L−1 hydrochloric acid solution in ethylene glycol, after a step of crushing and milling to powder size. Afterwards, cobalt, copper and iron were extracted from the leachate with 50 wt% Aliquat 336® in toluene, which was pre-saturated with 37 wt.% hydrochloric solution.

Parameters optimized for the solvent extraction of the transition metals were: the temperature, the feed/solvent ratio and the hydrochloric acid concentration. The extraction kinetics were also studied as well as the required number of stages for upscaling in mixer-settlers, this last through the construction of McCabe-Thiele diagrams.

Cobalt was stripped from the loaded solvent by a 0.5 mol L−1 aqueous hydrochloric acid solution. A 5 vol.% aqueous ammonia solution served to strip copper and to precipitate iron. whereas iron precipitated under these conditions.

The solvent could be reused after regeneration, i.e. evaporation of water and ammonia and reintegration of toluene and hydrochloric acid. Samarium was recovered from the hydrochloric acid-ethylene glycol raffinate by extraction with 20 vol.% Cyanex 272 in n-dodecane, followed by precipitation stripping with a 0.2 mol L-1 aqueous oxalic acid solution. The purity of the recovered cobalt chloride was 98.3 wt% and that of samarium oxalate was 99.4 wt%.

Biography Martina Orefice

Martina Orefice graduated in Environmental Sciences (BSc) in 2010 and in Chemical Engineering (BEng) in 2012 and (MEng) in 2015 at the University Federico II of Naples (Italy), her birth-city. Passionate for environmental issues thanks to a board game in her childhood, Martina aims to be a professional in secondary raw materials and circular economy.

Martina Orefice graduated in Environmental Sciences (BSc) in 2010 and in Chemical Engineering (BEng) in 2012 and (MEng) in 2015 at the University Federico II of Naples (Italy), her birth-city. Passionate for environmental issues thanks to a board game in her childhood, Martina aims to be a professional in secondary raw materials and circular economy.

Acknowledgements

The research leading to these results received funding from the European Community’s Horizon 2020 Programme ([H2020/2014-2019]) under Grant Agreement no. 674973 (MSCA-ETN DEMETER) and from the European Research Council (ERC) under the European Union’s

Horizon 2020 Research and Innovation Programme: Grant Agreement 694078—Solvometallurgy for critical metals (SOLCRIMET). This publication reflects only the authors’ view, exempting the Community from any liability. The authors want to thank Magneti Ljubljana d.d. (Slovenia) for providing the SmCo permanent magnets, Tony Debecker and Kevin Wierinckx for crushing the magnets, Dr. Jeroen Jordens for the particle size measurements, Dr. Jeroen Sniekers for the SEM and EDS analysis, Dr. Nagaphani Kumar Batchu for the very helpful discussion and Dr. Bieke Onghena and Dr. Peter Tom Jones for reviewing and editing the manuscript.

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)