SIM² KU Leuven is delighted to announce that it has just launched a new Industrial Service Centre, which is focussed on developing and commercialising solvometallurgical flow sheets or key elements within larger flow sheets that combine pyro-, hydro- and solvo-parts. SOLVOMET’s mission is to support its industrial and RTD partners in the conceptual and practical development of more sustainable solvometallurgical separation processes and new mining chemicals, which are subsequently tested using state-of-the-art lab-scale and mini pilot-scale experimental facilities.

SIM² KU Leuven is delighted to announce that it has just launched a new Industrial Service Centre, which is focussed on developing and commercialising solvometallurgical flow sheets or key elements within larger flow sheets that combine pyro-, hydro- and solvo-parts. SOLVOMET’s mission is to support its industrial and RTD partners in the conceptual and practical development of more sustainable solvometallurgical separation processes and new mining chemicals, which are subsequently tested using state-of-the-art lab-scale and mini pilot-scale experimental facilities.

What is solvometallurgy?

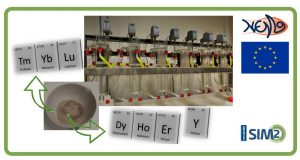

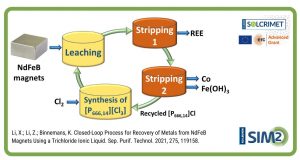

Solvometallurgy is to be considered as an emerging branch of extractive metallurgy. In contrast with hydrometallurgy, solvometallurgy employs non-aqueous solutions to extract metals from ores, industrial process residues, production scrap and urban waste. In order to position this emerging branch, Prof. Koen Binnemans (holder of ERC Advanced Grant SOLCRIMET – Solvometallurgy for critical metals) and Dr. Peter Tom Jones recently authored a position (open access) paper to present the opportunities and challenges for this exciting development within the metallurgy domain (J. Sustain. Metall. (2017) 3:570–600). Download here).

SOLVOMET: goal and mission

SOLVOMET is developed as a Service Centre for its industrial partners and large RTD Centres, who are leading actors in the fields of primary mining, mining chemicals and chemical metallurgy. The Centre is set up to industrially valorise the expertise in solvometallurgy that has been and is being developed in Prof. Koen Binnemans’ Research Group (Department of Chemistry, KU Leuven, Belgium) and his associated ERC Advanced Grant SOLCRIMET project. The Centre works in synergy with the HiTemp Centre and SIM² KU Leuven, as the goal is to embed the developed chemicals and processes into zero-waste valorisation flow sheets for base and critical-metal-containing End-of-Life waste as well as low-grade primary ores, extractive waste and industrial process residues.

SOLVOMET’s mission is to support its industrial and RTD partners in the conceptual and practical development of more sustainable solvometallurgical separation processes and new mining chemicals, which are subsequently tested using state-of-the-art lab-scale and mini pilot-scale experimental facilities. The mission of the Centre also includes upscaling the processes and solutions that have been developed on a lab-scale towards a mini-pilot-scale, thus taking Technology Readiness Levels (TRL) from 3-4 to 5-6.

C3 KU Leuven SO(VO)MET project

In order to help establishing this new Industrial Service Centre, the Industrial Research Fund of KU Leuven has recently funded an internal C3 KU Leuven project: SO(VO)LMET (Solvometallurgy for base and critical metals). This project provides 350 k€ of leverage funding for mini-pilot scale investments (solvometallurgical leaching equipment) and for developing upscaling science/technology skills (for a selection of generic case-studies).

New SOLVOMET website

Since September 2017, SOLVOMET also has a brand new website, which provides in-depth information about the solvometallurgy domain (incl. review paper on the benefits of solvometallurgy), the available research facilities that are offered to the industrial/RTD partners, the top achievements in the area, the service offer and a very comprehensive resource library containing a multitude of relevant peer-reviewed publications by the SOLVOMET founders (Binnemans & Jones) and researchers.

The service offer to companies and RTD Centres ranges from (1) Targeted literature reviews; (2.) Consultancy assignments, (3) Lab-scale feasibility studies, (4) Analytical services, (5) Upscaling/mini pilot-scale tests on solvometallurgical leaching, solvent extraction etc.

More information?

If want to know more about this new Service Centre, please contact Prof. Koen Binnemans or Dr. Peter Tom Jones: https://solvomet.eu/contact/

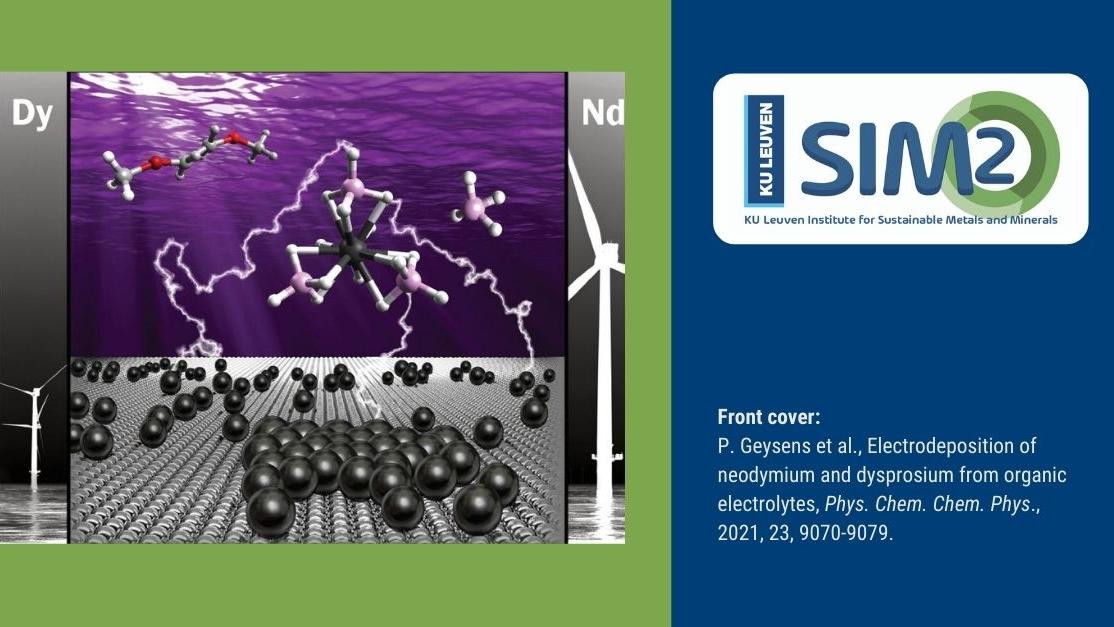

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)