On May 12, 2017, Sofía Riaño (KU Leuven, ESR7 in MC-ITN EREAN) successfully defended and obtained her PhD degree at KU Leuven. The topic of Riaño’s PhD dissertation is “Recovery of Neodymium and Dysprosium from NdFeB Magnets using Ionic Liquid Technology”. She obtained this degree in the framework of the EU FP7 Training Network Project, EREAN, which stands for the European Rare Earth (Magnet) Recycling Network. Dr. Riaño was supervised by Prof. Koen Binnemans (KU Leuven). The full text will become available once all research results have been officially published in the peer-reviewed literature. The already published papers can be found below. Dr. Riaño will now continue her research career as a postdoc in the group of Prof. Koen Binnemans where she will work on the PLATIRUS and NEOHIRE projects.

Publications by Sofía Riaño in the framework of this PhD

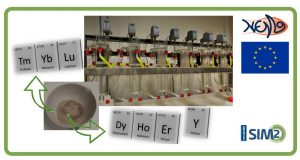

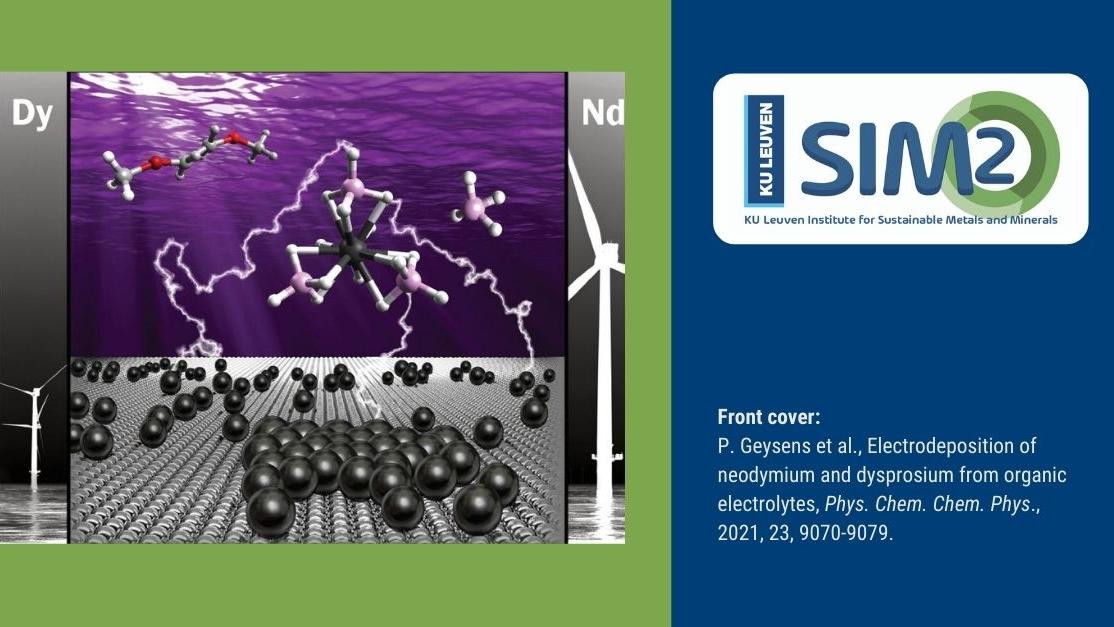

- Riaño, K. Binnemans; Extraction and separation of neodymium and dysprosium from used NdFeB magnets: an application of ionic liquids in solvent extraction towards the recycling of magnets. Green Chemistry 2015, 17, 2931-2942. Download here

- Riaño, M. Regadío, K. Binnemans, T. Vander Hoogerstraete; Practical guidelines for best practice on Total Reflection X-ray Fluorescence spectroscopy: Analysis of aqueous solutions. Spectrochimica Acta part B 2016, 24, 109-115. Download here

- Regadío, S. Riaño, K. Binnemans, T. Vander Hoogerstraete; Direct analysis of metal ions in solutions with high salt concentrations by Total Reflection X-ray Fluorescence (TXRF). Analytical Chemistry, 2017, 89, 4595-4603.

- Riaño, M. Petranikova, B. Onghena, T. Vander Hoogerstraete, D. Banerjee, M. R.StJ. Foreman, C. Ekberg, K. Binnemans; Separation of rare earths and other valuable metals from deep-eutectic solvents: a new alternative for the recycling of used NdFeB magnets. RSC Advances. (submitted and under review).

- Riaño, K. Binnemans. “Separation of neodymium and dysprosium using a phosphonium thiocyanate ionic liquid combined with neutral extractants: a process relevant for the recycling of end-of-life NdFeB magnets”. (To be submitted to Hydrometallurgy)

- Kontoulis, B. Sprecher, T. Vander Hoogerstraete, S. Riaño, K. Van Acker; “Environmental assessment of newly developed rare earth recycling routes out of end-of-life NdFeB permanent magnets”. (To be submitted to Journal of cleaner production).

Abstract PhD Sofía Riaño

The rare-earth crisis of 2010 taught the whole world a lesson: the supply of elements that are of high importance for the economy and the development of new technologies (i.e. the critical raw materials) must not rely only on a specific country or region. Investing in primary mining, research for the substitution of rare earth elements in their applications, development of rare-earth recycling schemes and training of highly skilled personnel constituted a set of strategies proposed by Europe to tackle the shortage of rare earths.

The recycling of neodymium-iron-boron (NdFeB) permanent magnets is more interesting from an economic and environmental point of view than the opening of new mines. Additionally, elements high in demand and less abundant, such as dysprosium, can be easily recovered. Other critical and valuable metals can also be recovered as byproducts from the recycling of NdFeB permanent magnets. The recovery and purification of individual rare earths opens the possibility to their reuse in the fabrication of magnets with different compositions for specific applications.

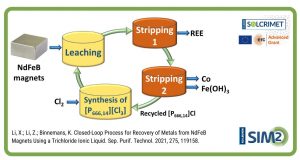

Ionic liquids can be employed as a green alternative to replace the conventional organic phase in solvent extraction processes of rare-earth elements. In this thesis, different approaches involving ionic liquids were developed to recover neodymium, dysprosium and other valuable metals such as cobalt from NdFeB magnets. The extractions were carried out from nitrate and chloride media. The addition of a molecular extractant was also studied and it provided a beneficial lower viscosity of the organic phase and a higher loading capacity in comparison with the pure ionic liquid.

In a new approach, the deep-eutectic solvent choline chloride:lactic acid (molar ratio 1:2) was employed to dissolve the magnets. The solvent extraction process was carried out by contacting the deep-eutectic solvent (more polar phase) with ionic liquids and conventional extractants diluted in toluene (less polar phase). Iron, boron and cobalt were separated from neodymium and dysprosium using the ionic liquid tricaprylmethylammonium thiocyanate (Aliquat® 336 SCN) diluted in toluene. The separation of neodymium and dysprosium was assessed by using Cyanex® 923 and the feasibility of scaling up this separation process was tested in a mixer settler setup.

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)