The EU Horizon 2020 Remaghic project on “New Recovery Processes to produce Rare Earth -Magnesium Alloys of High Performance and Low Cost” has come to an end. The key results obtained in this Innovation Action project are summarised by Blanca Araujo Perez (CIDAUT, Spain) and Dr. Federica Forte (KU Leuven, Belgium) in a high-profile interview in the Journal Impact. Impact is a series of leading, high-quality science reports that enables the communication of research impact in a format and language that diverse stakeholders will understand. (PTJ, 24/10/2018)

Read the interview about Remaghic

The Remaghic project, the work of a consortium of leading universities, research institutions and private companies, seeks to develop new recovery processes to produce high-performance, low-cost rare earth-magnesium alloys. In this interview you can read about the main results obtained in this 3-year project. You can download the interview here.

The Remaghic project, the work of a consortium of leading universities, research institutions and private companies, seeks to develop new recovery processes to produce high-performance, low-cost rare earth-magnesium alloys. In this interview you can read about the main results obtained in this 3-year project. You can download the interview here.

About Remaghic

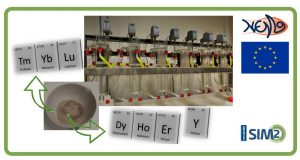

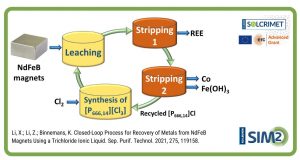

Remaghic is a 3-year EU Horizon 2020 project focused on the development of new Mg-REEs alloys of improved mechanical properties and reduced price. In WP1, new techniques have been developed for the recovery of REEs (Y, La and Ce) from several waste streams (namely lamp phosphors, CRT phosphors and NiMH batteries).

is a 3-year EU Horizon 2020 project focused on the development of new Mg-REEs alloys of improved mechanical properties and reduced price. In WP1, new techniques have been developed for the recovery of REEs (Y, La and Ce) from several waste streams (namely lamp phosphors, CRT phosphors and NiMH batteries).

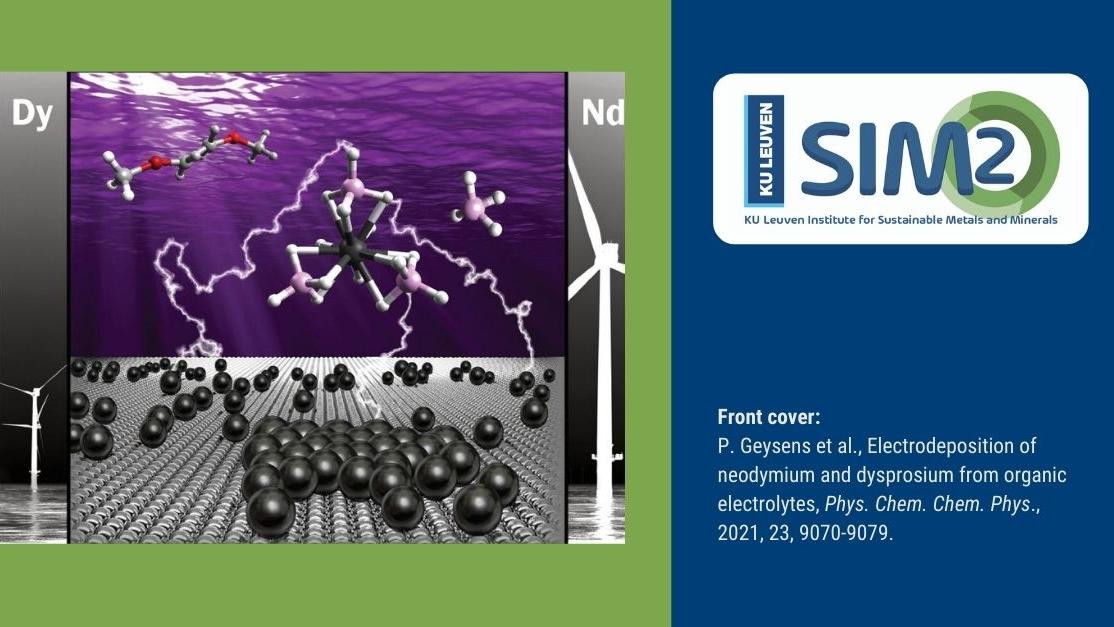

These techniques are based on low-mid temperature processes (HydroWEEE process, iono- and solvometallurgical methods) and high-temperature processes (roasting and pyrometallurgical methods). New processes have been also developed for the recycling of magnesium from scrap and scum within WP2.

The achieved results fed WP3, focused on the alloying process between Mg and REEs, while WP4 targeted the industrial scaling to ensure that the methodologies developed in the previous WPs can be used to produce industrially viable quantities of materials.

Finally, a detailed Life Cycle Assessment (LCA) study was performed in WP5 in order to determine the most cost-effective option for recovering and alloying magnesium and REEs and to quantify the economic and environmental benefits of the overall process. The project will contribute to reduce the dependency of the supply of critical elements (REEs and Mg) on sources exterior to the EU and to partially mitigate the Balance Problem, by offering new applications for those REEs which are usually stockpiled (such as La and Ce).

Biographies

Blanca Araujo is a senior industrial engineer and a Lean Project Manager. Blanca has more than 10 years of experience in material modelling and simulation. In the last eight years she has worked as project and innovation manager. She has worked in product design and component development for several OEMs and Tier1 within the transport industry. As Project Manager, she has managed research and development projects related to material development, manufacturing and product development projects. She is Remaghic project coordinator.

Federica Forte is a postdoctoral researcher in the Department of Chemistry at KU Leuven, Belgium. Her main interests are in the field of hydrometallurgy, ionometallurgy and solvometallurgy. In particular, she has been involved in the development and optimisation of critical raw material (CRM) recovery processes from several types of residues such as fly ash, WEEE and metallurgical slags.

Federica Forte is a postdoctoral researcher in the Department of Chemistry at KU Leuven, Belgium. Her main interests are in the field of hydrometallurgy, ionometallurgy and solvometallurgy. In particular, she has been involved in the development and optimisation of critical raw material (CRM) recovery processes from several types of residues such as fly ash, WEEE and metallurgical slags.

Acknowledgements

The Remaghic project has been supported by funding from the European Union’s Horizon 2020 Research and Innovation programme under grant agreement number 689629.

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)