| A new rare-earth magnet recycling process developed by researchers at the Critical Materials Institute (CMI) dissolves magnets in an acid-free solution and recovers high purity rare earth elements. For shredded magnet-containing electronic wastes, the process does not require pre-processing such as pre-sorting or demagnetization of the electronic waste.

Rare earths are vital to many technologies and are critical ingredients in the world’s strongest magnets, but they are subject to supply shortages. Recycling is a possible solution to the supply-chain problems, but until now has faced serious economic and ecological challenges. CMI, a U.S. Department of Energy Innovation Hub led by Ames Laboratory, was able to overcome several hurdles to the environmental viability of rare-earth recycling with this processing technology, according to lead researcher Ikenna Nlebedim. “The difficulty with traditional hydrometallurgical methods for rare-earth magnet recycling is that they rely on the use of hazardous mineral acids, and this presents a number of problems from an economic and environmental standpoint,” said Nlebedim. “It produces toxic fumes; the acids need to be contained, and so do acid-contaminated wastes.” The new process has been applied to waste magnet materials obtained from U.S. magnet processing plants. “The technology is remarkably selective in recovering rare-earth elements even from chunks of magnet-containing shredded electronic wastes,” said Nlebedim. In shredded computer hard drives for example, rare earth elements were selectively removed from the e-waste without the need to pre-sort or pre-concentrate the magnet content of the materials, further reducing steps and costs. The result is recovered rare-earth oxides of high purity, without the production of fumes or use of hazardous mineral acids. The process has been adapted for the recovery of rare earth elements from both Nd-Fe-B (Neodymium-Iron-Boron) and Sm-Co (Samarium-Cobalt) magnets. Other valuable by-products of e-waste components can be recovered for further recycling including copper, chromium, nickel and other metals or their composites. “Available rare earth elements recovery methods are rarely profitable” said postdoctoral researcher Denis Prodius. “This method not only recovers high-purity rare earths, it also recovers other marketable materials. The by-products pay for chemicals used in the recycling process.” For information regarding the licensing of this technology, contact Craig Forney at Iowa State University’s Office of Intellectual Property and Technology Transfer, 515-294-9513, ceforney@iastate.edu. The Critical Materials Institute is a Department of Energy Innovation Hub led by the U.S. Department of Energy’s Ames Laboratory and supported by DOE’s Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office, which supports early-stage applied research and development of new materials, information, and processes that improve American manufacturing’s energy efficiency, as well as platform technologies for manufacturing clean energy products. CMI seeks ways to eliminate and reduce reliance on rare-earth metals and other materials critical to the success of clean energy technologies. Ames Laboratory is a U.S. Department of Energy Office of Science national laboratory operated by Iowa State University. Ames Laboratory creates innovative materials, technologies and energy solutions. We use our expertise, unique capabilities and interdisciplinary collaborations to solve global problems. Ames Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov. |

Don't Miss

- Join us at ICHS 2024 Symposium (9-11 Sep 2024, Mechelen)

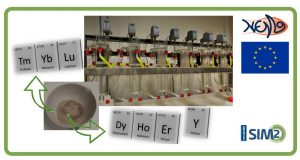

- Heavy rare-earth separation process successfully tested on pilot-scale level

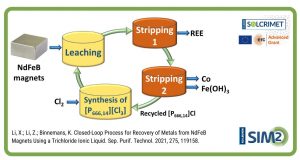

- Closed-loop process for Co & REE recovery from NdFeB magnets

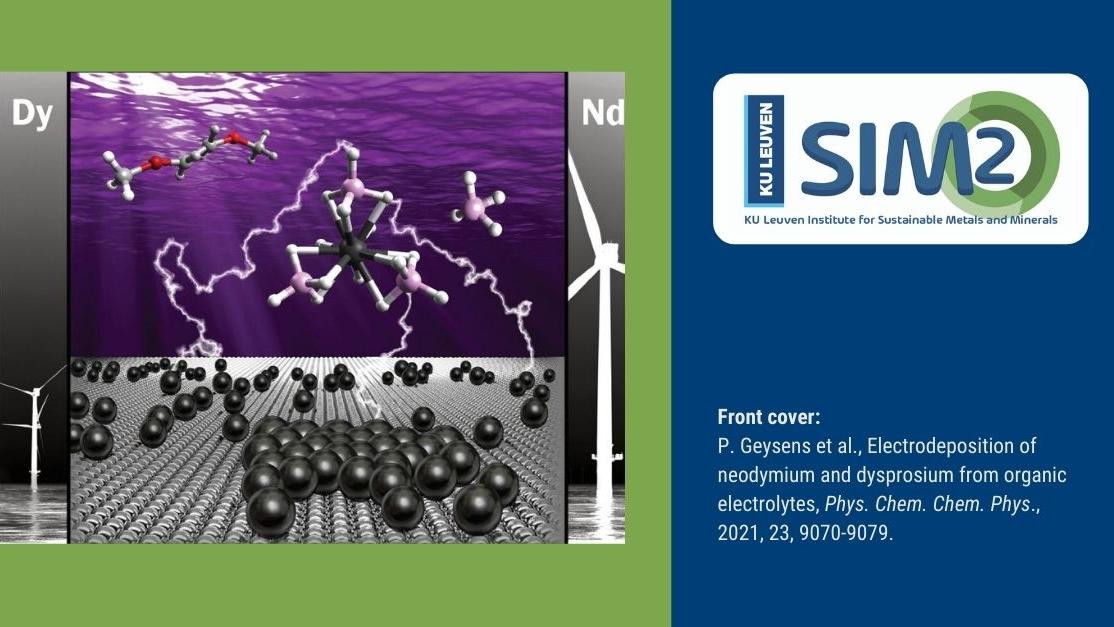

- Electrodeposition of neodymium and dysprosium from organic electrolytes

- Rare-earth recycling needs market intervention (Nature Reviews Materials)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)