SIM² KU Leuven – SOLVOMET researchers developed a new closed-loop metal recovery process for NdFeB-based permanent magnets. Using an oxidative ionic liquid, which can be reused in next cycles, the process allows to recover both the rare-earth metals and cobalt from the spent NdFeB magnets. The process comprises dissolution, stripping and regeneration of the ionic liquid. The work was published in the journal Separation and Purification technology.

Rare-earth elements (REEs) are essential for various high-tech applications, such as rechargeable batteries and permanent magnets. Currently, neodymium-iron-boron (NdFeB) permanent magnets represent the largest share of the permanent magnet market. The supply risk of REEs demands the recycling of these critical metals from secondary resources such as pre-consumer industrial production scrap and end-of-life products.

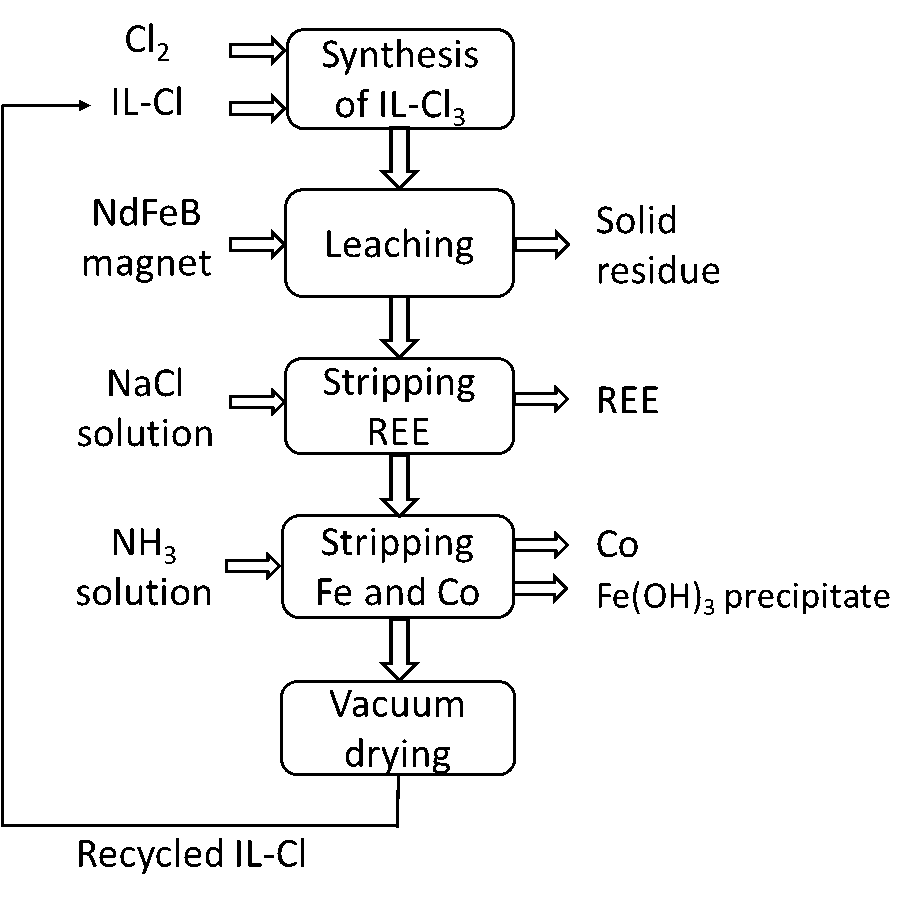

A solvometallurgical process was developed to recover rare-earth elements and cobalt from end-of-life NdFeB magnets, using the ionic liquid (IL) trihexyltetradecylphosphonium trichloride ([P666,14][Cl3]), or a mixture of [P666,14][Cl3] and the corresponding chloride IL [P666,14]Cl (in Figure 1). Full dissolution of NdFeB magnets could be obtained at an appropriate solid-to-liquid ratio. Two stripping steps using aqueous NaCl and NH3 solutions can remove rare-earth metals and transition metals sequentially from the IL, respectively.

The reusability of IL promotes the sustainability of the process. However, the high viscosity of IL is still an issue which holds back its large scale applications. Therefore, less viscous oxidative IL needs to be developed in the future.

Figure 1. Closed-loop process for the recovery of metals from end-of-life NdFeB magnets using a mixture of the trichloride ionic liquid [P666,14][Cl3] and the chloride ionic liquid [P666,14]Cl.

Biography lead author

Xiaohua Li started her postdoc research within the SOLVOMET Group of Prof. Koen Binnemans at KU Leuven from November 2016, after obtaining her doctor degree from university of Twente in the Netherlands. Since September 2019, she has been working on her FWO postdoctoral grant to develop new ionic liquid-based aqueous biphasic system for rare-earth metal recovery. Her main research interests include solvent extraction, oxidative dissolution of metals, metal recovery, aqueous biphasic system and ionic liquids.

Xiaohua Li started her postdoc research within the SOLVOMET Group of Prof. Koen Binnemans at KU Leuven from November 2016, after obtaining her doctor degree from university of Twente in the Netherlands. Since September 2019, she has been working on her FWO postdoctoral grant to develop new ionic liquid-based aqueous biphasic system for rare-earth metal recovery. Her main research interests include solvent extraction, oxidative dissolution of metals, metal recovery, aqueous biphasic system and ionic liquids.

Full reference paper

Li, X.; Li, Z.; Binnemans, K. Closed-Loop Process for Recovery of Metals from NdFeB Magnets Using a Trichloride Ionic Liquid. Sep. Purif. Technol. 2021, 275, 119158. https://doi.org/10.1016/j.seppur.2021.119158

Acknowledgements

The research leading to these results received funding from a postdoctoral grant of the Research Foundation Flanders (FWO) to X. Li (12ZA520N). The research was funded by the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078—Solvometallurgy for critical metals (SOLCRIMET). Zheng Li acknowledges the senior FWO postdoctoral Fellowship (181203/12ZI920N).

.png)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)

European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER)